One site detailed the procedure and listed

the materials that were used. The person used a two part High performance polyester

urethane from Forsch Polymer Corp. I called Forsch and told their technician exactly

what I wanted to do with their product, he told me their product has been used by

many people to rebuild motor mounts and recommended their medium durometer

high tear strength system, 60A with their ADH 1001 urethane to metal primer.

Click on a picture to bring up a larger image in a new window.

|

|

|

|

|

| This is one of my original motor mounts, it

rough shape, it was still stuck together, the other mount's rubber cushion fell

apart when I removed it from the car. I measured the cushion from the other mount

to determine the distance of separation of the two parts. I measured about an 1/2"

but figure I should add a little to compensate for compression over the last 70

years.

|

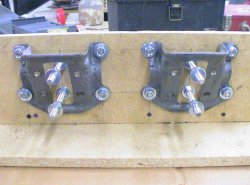

I made a jig/stand out of 1/2" particle board

to mount the mounts to. I measured the mounting holes of both the motor side and

the frame side and marked and drilled holes in the upright board. I recessed all

of the holes so I could fasten the bolts with a nut on the front, keeping the mounting

surface of the motor mount flush on the particle board. I used 3/8"x1 1/2" for the

motor side and 3/8" threaded rod and nuts to mount the frame side of the motor mount.

I used nuts to keep the two pieces separated the correct distance.

|

|

|

|

|

As per instructions, I sand blasted the parts so the polyester

urethane had a good, clean surface to bond to. The Forsch tech also suggested drilling

larger holds in both parts to assure a mechanical bond as well as an adhesion bond.

I applied the recommended primer. It brushes on wet but when dry it's almost invisible.

I covered all bonding surfaces, including the inside and areas around the holes I drilled.

|

|

|

|

|

I bolted the mounts to the stand. I tried to

seal off the mounts the best I could so I wouldn't have a lot of spillage and wasted

product, I wasn't too successful. I figured one can of urethane should have been

enough for both mounts but ended up using one can for just one mount. I used a roll of

light weight 6" wide aluminum roof flashing and plumber's putty to seal the mounts. I was only

able to do one and it was a mess, for the second one I will do better. I also used

cardboard to seal the inside cavity of the mount, this is where all of my leakage occurred.

I lined the cardboard with plastic packing tape to prevent the urethane from sticking to

it, it worked pretty good. The flashing peeled off fairly easy without coating it.

|

|

|

|

|

| Here are the results. Not very pretty but

they're going to be under the car getting greasy and dirty and no one will ever see

them. They'll also look a lot better with a coat of black paint on them.

I had to do some trimming of the urethane and had a little difficulty

separating the mount from the stand but it wasn't all that hard. Well worth the

$150 savings and being able to say I was able to do another job on my car myself.

|

|

|

| I recently cast the remaining rear mount and the

bottom and top parts of the front mounts.

|

Because the front mount trays were pretty beat up

I built new ones.

|

| Total cost for the entire project: |

2 urethane kits

Way more than enough to do

all the parts, as long

you're able to dam the parts properly. |

$70 |

Urethane primer

One can is more than enough for

at least 6 urethane kits |

$12 |

Shipping

(for both kits, two shipments) |

$10 |

Misc. Hardware

(nuts, bolts, washers) |

$2 |

| Plumbers putty (for damming) |

$2 |

| Paint |

$5 |

| Solvents |

$5 |

| Total |

$106 |

| Total time for the entire project: |

| Blast parts |

2 hours |

| Built fixtures |

2 hours |

| Set up parts |

2 hours |

| Mix and Pour urethane |

1 hour |

| Clean excess urethane from parts |

1 hour |

| Paint parts |

1 hour |

| Total estimated time |

9 hours |

|

| Total cost to have mounts rebuilt and new

parts: |

| Cost to have rear rebuilt |

$170-200 |

| New front mounts |

$70.00 |

| Front donuts |

$13.50 |

Shipping

(including two way for rear mounts) |

$30-40 |

| Total |

(roughly) $240-325 |

| Total time for the entire project: |

Order parts over phone |

1/2 hour |

Find box and box up parts |

1 hour |

| Send parts off and wait for return |

3-4 Weeks |

| Total estimated time |

1 1/2 hour

plus3-4 weeks |

|

|

|